Implementation of barcode technology in steel manufacture

SSSC plans to implement the technology of barcodes and detecting origins of goods in manufacture.

In preparation for 4th Industrial Revolution, despite the top position on the market of color coating steel sheets, SSSC has continuously invested in technology to meet the diverse demand in applications and the target of top quality.

It is SSSC’s policy to emphasize on technological investment that has become the lever to make the brand more popular with the domestic customers and honorably become one of 97 brands that win Vietnam Value 2018.

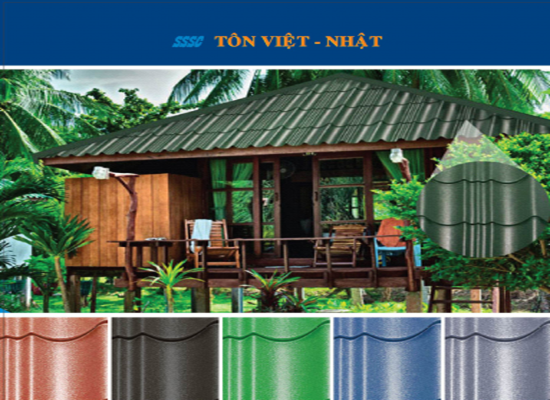

Established on June 22, 1995, SSSC was a joint venture of Vietnam Steel Corporation with Sumitomo Corporation (Japan). During that time, this was the first corporate that introduced the advanced technology to produce galvanized and pre-painted color steel sheets in coil into Vietnam.

After 20 years of operation in Vietnam, the sales of SSSC’s products in general and galvanized steel sheets in particular has continuously expanded in all over the country. Currently, there are 50 agents and distributors in provinces and cities from North to South. With outstanding quality, modern technology, SSSC’s products not only have solid position in the Vietnam market but can compete with similar products in the markets of neighboring countries.

According to Mr. Nguyen Thanh Binh, specialist in construction of commercial housing, he always prioritize in good-quality products with reasonable price. Many of his customers requires steel sheets with reliable brand and he decides on SSSC’s products in processing and production.

All of the transparent information about the product shows that SSSC always commit to bring the best-quality products to customers, ensure the sustainability of each construction work. To SSSC, customers’ trust comes from the prestige of the brand.

Mr. Le Viet, SSSC’s 1st Deputy General Director says: In SSSC always proceeds with cautious and serious steps on the basis of total compliance with the quality policy, continuously modernizing the technology, pioneering all advanced technology trends.

One milestone that marked SSSC’s progress is the investment in the great and effective lines on 20th anniversary including a continuous galvanizing line with the NOF technology and the capacity of 100,000 tpy; a continuous galvalume line with the NOF technology from Tenova (Italy) with the capacity of 170,000 tpy; 2 color coating lines with capacity of 140,000 tpy.

With the total investment of VND 1,400 billion or USD USD 70 million, the new factory has increased SSSC’s capacity by three times since its operation.

This is one of the important targets for SSSC to achieve to become one of the top suppliers of steel sheets in South East Asia.

According to Pham Anh Tuan, SSSC’s Marketing Manager to continue the sustainable growth, improve the competitiveness, especially to protect the users, during the booming of technology, SSSC has applied the 4th technological generation by the use of barcodes to detect the origin of goods in production. When it is done, SSSC will become the first enterprise that successfully applies barcode management technology in steel production.

The reason for the implementation of this technology is that counterfeit products has been causing confusion to customers who cannot distinguish them with the real products. Therefore, the use of origin detecting technology will help dealing with low-quality of fake products and controlling the goods transparently.

Simultaneously, it helps to restrain the quantity of bad-quality or counterfeit in the market and helps the customers to approach the most transparent and sufficient information system. The origin of products can be traced from the stages of material, manufacture, packing, transportation and distribution.

Especially, the use of barcodes is considered as the way to protect the prestige of the manufacturer as well as the benefits of the customers./.

Orther news

YEAR-END PARTY AND APPRECIATION CUSTOMERS IN THE SOUTH, THE CENTRAL – HIGHLAND REGION AND EXPORT MARKETS

05/02/2024

NIPPOVINA CONFERENCE JANUARY 11th, 2024

15/01/2024

MR. HIROSHI MURAKAMI, CHAIRMAN AND GENERAL DIRECTOR OF SUMITOMO CORPORATION GLOBAL METALS CO., LTD VISITED AND WORKED AT PHUONG NAM CORPORATION COMPANY.

15/01/2024

SSSC SPEEDS UP THE DIVERSIFICATION OF HIGH-END AND TASTEFUL ROOFINGS

SSSC’S COMMENCEMENT OF THE PROJECT “CONSTRUCTION OF CGL WITH CAPACITY 150,000 TPY AT NHON TRACH”

SSSC AND THE GRAND OPENING

SSSC and the summit of Vietnam Value 2018

SSSC – Technological investment is always a profitable one

Southern Steel Sheet Co., Ltd. Gets The First “Vietnam Value” Certificate

SSSC INCREASES THE EXPORT OF COATED STEEL SHEETS TO THE U.S. MARKET IN QUARTER 3, 2018

MEETING WITH THE FUTURE LEADERS

SSSC (VIETNAMESE – JAPANESE STEEL SHEET) PARTICIPATED IN THE 1ST VIETBUILD INTERNATIONAL EXHIBITION IN HO CHI MINH CITY

SOUTHERN STEEL SHEET CO. LTD. AND THE SPEED-UP IN EXPORT TO THE U.S. MARKET IN 2018 – 2020