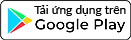

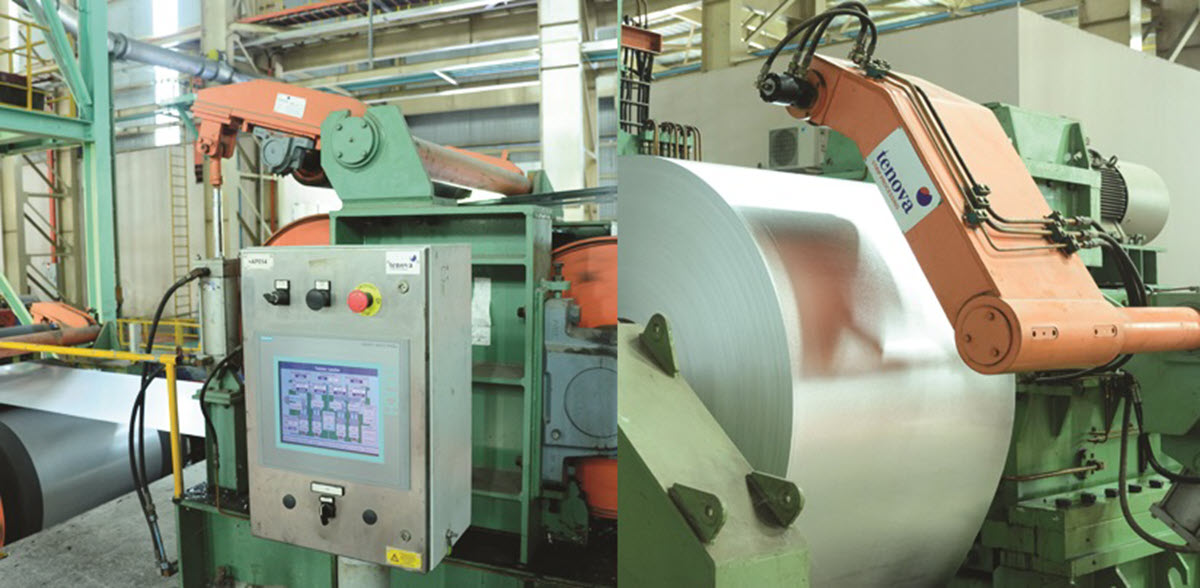

Continuous galvanized/aluminum-zinc coating line

SSSC’s aluminium-zinc coated steel sheet in coil (GL) is produced by the advanced NOF hot-dip continuous galvanizing line. The product has a very good corrosion resistance in the natural surroundings.

SSSC’s GL coil has the glossy surfaces, its machinability is suitable for applications of fabrication, forming, etc.

The SSSC’s GL is manufactured in compliance with the standards: JIS G3321, ASTM A792/A792M, SSSC’s standard: TCCS-03.

Specifications of product

| Thickness (mm) | 0.16 + 1.5 |

| Width (mm) | 1250Max. 1250 |

| Unit coil weight (ton) | Max. 25 |

| Average coating mass on both sides at triple-spot | 300 |

| Coil inner diameter (mm) | 508 or 610 |

Coating treatment

- Regular spangle

- Mini spangle

Finishing

- Chromated treatment

- Oiling

- Anti-finger resin (color, no color)

Production process chart

QUALITY STANDARDS (SSSC’s standard – TCCS-03)

T-BEND: ≤ 2T

Coating thickness

| Coating standard | Minimum coating mass in triple-spot test (g/m2) | Minimum coating mass on both sides at single-spot (g/m2) |

| AZ50 | 50 | 43 |

| AZ60 | 60 | 51 |

| AZ70 | 70 | 60 |

| AZ90 | 90 | 76 |

| Z100 | 100 | 85 |

| AZ120 | 120 | 102 |

| AZ150 | 150 | 130 |

| AZ170 | 170 | 145 |

| AZ185 | 185 | 160 |

| AZ200 | 200 | 170 |

* Remarks: The standards of other coating thickness shall be agreed between the manufactuer and the purchaser.

Appearance: The product must be free from defects that are detrimental to its practical use.

Thickness tolerances

| Nominal thickness | Width < 1000 mm | Width ≥ 1000 mm |

| < 0,25 | ± 0,04 | ± 0,04 |

| 0,25 ÷ < 0,40 | ± 0,05 | ± 0,05 |

| 0,40 ÷ < 0,60 | ± 0,06 | ± 0,06 |

| 0,60 ÷ < 0,80 | ± 0,07 | ± 0,07 |

| 0,80 ÷ < 1,00 | ± 0,07 | ± 0,08 |

| 1,00 ÷ < 1,25 | ± 0,08 | ± 0,08 |

| 1,00 ÷ < 1,25 | ± 0,08 | ± 0,09 |

| 1,25 ÷ < 1,50 | ± 0,10 | ± 0,11 |

Width tolerances: 0 ÷ + 7mm

Flatness

Unit: mm

| Width | Type | |

| Wavy-edge (max) | Center buckling (max) | |

| < 1000 mm | 8 | 6 |

| ≥ 1000 mm | 9 | 8 |

Physical properties

| Thickness (t) mm | H1 | S1 | S2 | |

|

Tensile Strength (Mpa) |

0.30 ≤ t | 550 - 800 | 270 - 400 | 401 - 549 |

|

Yield Point (Mpa) |

0.30 ≤ t | - | ≥ 205 | ≥ 295 |

| Elongation (%) | 0.30 ≤ t <0.40 | - | ≥ 31 | ≥ 10 |

| 0.40 ≤ t <0.60 | - | ≥ 34 | ≥ 10 | |

| 0.60 ≤ t <1.0 | - | ≥ 36 | ≥ 10 | |

| 1.0 ≤ t <1.6 | - | ≥ 37 | ≥ 10 |

MARKING, PACKING AND MAINTENANCE

Packing

The product is packed either in accordance with the SSSC’s regulation or the customer’s requirement.

Transport and maintenance:

Transport: Transporting the product must avoid a big impact, which may be detrimental to quality, shape and appearance of the product.

Maintenance: It complies with the guide on maintenance attached on the product.

APPLICATIONS

Orther news