Prepainted color steel sheet

SSSC’s prepainted color steel sheet in coil (PPGI/PPGL) is manufactured from the steel base: SSSC’s GI/GL with the finish paint coating of either polyester or PVDF or SMP and the primer paint coating of either expoxy or PU.

SSSC’s PPGI/PPGL coil has the glossy surfaces, its machinability is suitable for applications of fabrication, forming, etc.

The SSSC’s PPGI is in accordance with the standards: JIS G3312, ASTM A755/A755M, SSSC’s standard: TCTMM.

The SSSC’s PPGL is in compliance with the standards: JIS G3322, ASTM A755/A755M, SSSC’s standard: TCCS04.

Samples of color of SSSC’s prepainted color steel sheet.-1_1596165636.jpg)

Specifications of product

| Thickness (mm) | 0.16 to 2.00 |

| Width (mm) | 1250 |

| Unit coil weight (ton) | 10 |

| Painting film thickness (µm) | 6 ÷ 30 |

| Coil inner diameter (mm) | 508 |

Production process chart

QUALITY STANDARDS (SSSC’s standards – TCTMK and TCCS-04)

- T-bend (both sides): ≤ 4T

- Erichsen: The rate of grids with painting layers peeled off is ≤ 5%

- Impact (applied to CQ quality only): The painting layer is not peeled off from the steel base.

- Pencil hardness: ≥ 3H

- Rubbing with M.E.K solvent: The painting layer is not peeled off from the steel base.

| Sides | Standard |

| Top finish | ≥ 100 dr |

| Bottom backer | ≥ 70 dr |

| Bottom monocoat | ≥ 70 dr |

Width tolererance: 0 ÷ 7 mm

Thickness tolerance: It shall apply to the thickness after prepainting.

| Nominal thickness |

Width< 1000 mm |

Width 1000 ÷ 1250 mm |

| < 0,25 |

+ 0,08 / - 0,03 |

+ 0,08 / - 0,03 |

| 0,25 ÷ < 0,40 |

+ 0,09 / - 0,04 |

+ 0,09 / - 0,04 |

| 0,40 ÷ < 0,60 |

+ 0,10 / - 0,05 |

+ 0,10 / - 0,05 |

| 0,60 ÷ < 0,80 |

+ 0,11 / - 0,06 |

+ 0,11 / - 0,06 |

| 0,80 ÷ < 1,00 |

+ 0,11 / - 0,06 |

+ 0,12 / - 0,07 |

| 1,00 ÷ < 1,25 |

+ 0,12 / - 0,07 |

+ 0,13 / - 0,08 |

| 1,25 ÷ < 1,50 |

+ 0,14 / - 0,09 |

+ 0,15 / - 0,10 |

Paint film

For 04 layers (Unit: µm)

|

Layers |

Paint coating |

| Finish layer | 12 ÷ 20 |

| Top primer layer | 5 ÷ 7 |

| Bottom primer layer | 5 ÷ 7 |

| Backer layer | 7 ÷ 10 |

For 03 layers (Unit: µm)

|

Layers |

Paint coating |

| Finish layer | 12 ÷ 20 |

| Top primer layer | 5 ÷ 7 |

| Bottom monocoat layer | 8 ÷ 10 |

* Remarks: The standards of other paint coatings shall be agreed by the manufacturer and the purchaser.

Gloss of paint coating

| Width | Type | |

| Wavy-edge (max) | Center buckling (max) | |

| < 1000 | 8 | 6 |

| >= 1000 | 9 | 8 |

Appearance: The product must be free from defects that are detrimental to its practical use.

| Sides | Duration (hrs) |

| Top side | ≥ 500 hrs |

| Bottom side | ≥ 200 hrs |

MARKING, PACKING AND MAINTENANCE

Packing

The product is packed either in accordance with the SSSC’s regulation or the customer’s requirement.

Transport and maintenance:

Transport: Transporting the product must avoid a big impact, which may be detrimental to quality, shape and appearance of the product.

Maintenance: It complies with the guide on maintenance attached on the product.

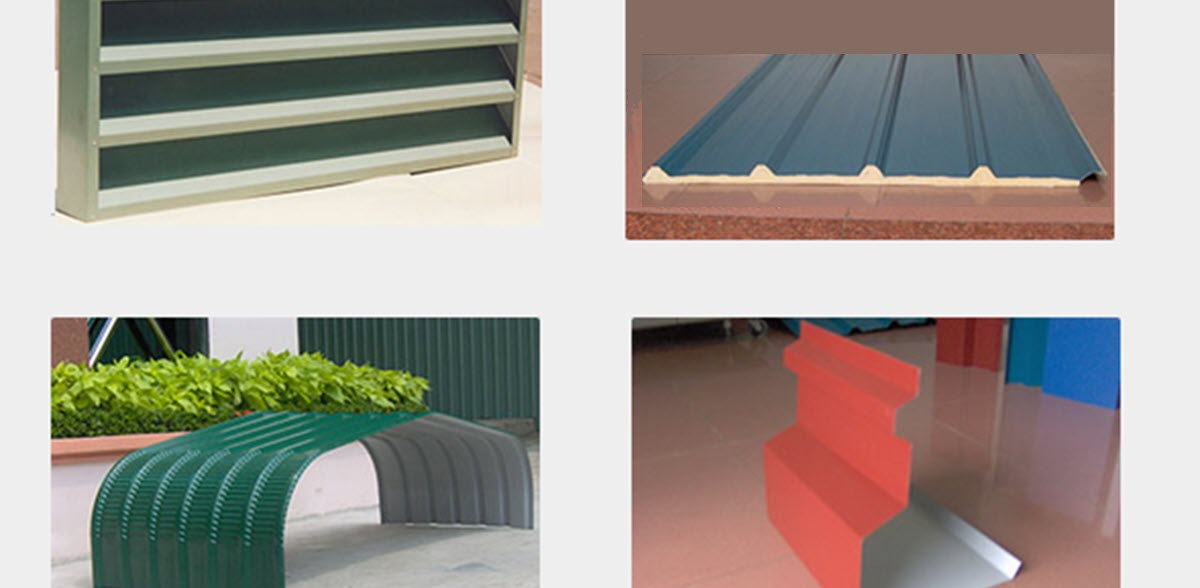

APPLICATIONS

Orther Product